On January 15, 2019, the Safe Food for Canadians Act and Regulations came into effect. The scope of the SFCR requirements is food that is imported, exported, and inter-provincially traded in Canada.

Regulatory compliance with SFCR ensures that “anyone who is importing, exporting, manufacturing, processing, treating, preserving, grading, packaging, or labelling […] food has not compromised food safety” (CFIA, 2019).

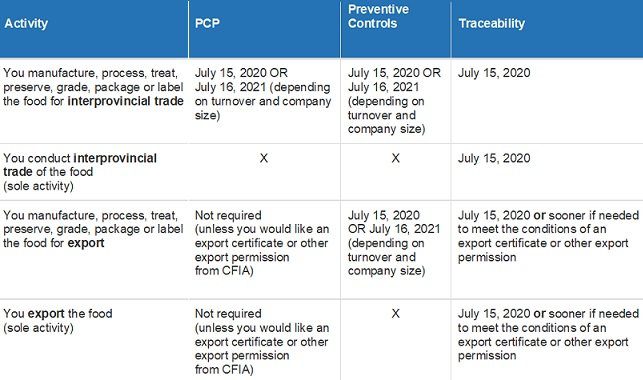

While most federal requirements apply to food products that are shipped across provincial boundaries, some SFCR provisions (ex: bilingual labeling of pre-packaged food) also apply to food sold within provincial borders. From July 15 2020, food products under the category of “Other Foods” — “confectionery, snack foods, beverages, oils, dried herbs and spices, nuts and seeds, coffee and tea, processed grain-based foods such as baked goods, cereals and pasta” — will be subject to licensing, preventive controls, traceability, and recordkeeping requirements.

This change affects Canadian businesses that ship products between provinces, as well as Canadian food importers.

PCP Implementation by 15 July 2020

A PCP is a written plan that outlines food safety risks and corresponding preventive measures, thereby providing assurance that food is safe to consume and conforms to grade, labelling and other standards of identity requirements. Control measures or “Preventive Controls” are designed to prevent, eliminate or reduce hazards to a safe and acceptable level. They are based on internationally recognized food safety principles (ex: Codex HACCP and Good Manufacturing Practices).

What are the 4 key PCP Requirements?

- Ensure that the food manufacturing establishment (domestic or foreign site) is conducive to food safety.

Canadian manufacturers and importers must ensure that the traded food originates from a manufacturing site that is operated and maintained according to sections 50 to 81 of the SFCR. In order to comply with these requirements, you will need to develop and put in place procedures to address plant sanitation and pest control, employee training, equipment maintenance and calibration, storage and distribution. For a full list of SFCR site requirements, refer to our audit checklist and guidance document. Download our audit checklist here.

- Perform a food safety risk assessment of the manufactured food.

Domestic food manufacturers and food importers must perform a thorough hazard analysis of the traded food and its components and identify food safety hazards (biological, chemical and physical). A careful review of inputs (raw materials, packaging, processing aids, ingredients) will be required at this step. The risk assessment must also consider hazards pertaining to the food process and employee/food flows within the manufacturing site. Hazards that are likely to occur will need controlling through the implementation of control measures. Based on risks, some control measures may be deemed critical. In this case, procedures will be applied at specific points in the process where control is required. These processes are referred to as “Critical Control Point Procedures.” In order to comply with the regulations, the domestic manufacturer or Canadian importer must verify the application of effective food safety measures. Food importers are required to complete and document verification activities to ensure that foreign sites have implemented controls. When deviations are identified, corrective actions must be taken and documented to ensure safety. The PCP plan must be updated whenever changes to the site, a process or a food formulation occur.

Technical knowledge will be needed to complete the hazard analysis and identify verification and corrective action procedures. The domestic manufacturing facility or food importer may need to request the services of a food safety consultant to complete this section of the PCP. Obtaining a food safety certification such as HACCP or GFSI is another robust way for a domestic or foreign site to prepare for SFCR compliance.

CFIA PCP Templates for domestic manufacturers and importers can be found at these links:

- Establish verification procedures for consumer protection/market fairness requirements.

This section of the PCP relates to food labeling, packaging, grading, standards of identity and net quantity (sections 89(1)(a) and (b) of the SFCR). The facility must ensure that the imported or prepared food is labeled according to the Food and Drugs Act and Regulations and that the integrity of the food is not compromised. Refer to the CFIA template for a full list of customer protection requirements.

- Establish Recall, Traceability and Customer Complaint Handling Procedures.

In addition to food safety and quality requirements, manufacturers and importers must be able to trace and recall food should it be deemed unsafe. Good traceability practices are based on recognized Codex standards. Businesses that prepare and ship food within Canada or which import food to be sold in Canada must develop recall and traceability plans (Sections 90 and 91 of the SFCR). Customer complaints may prompt the manufacturer or the importer to recall prepackaged food. Businesses must, therefore, develop a process to evaluate and respond to serious customer complaints.

For additional references, please consult the following CFIA guide: Understanding the regulations for food businesses – a handbook.

Sirocco provides PCP plan development services and SFCR procedure and form templates to meet site and recall/traceability/complaint requirements. Click here to see a list of the templates available.

You can purchase Sirocco’s SFCR Site Requirements Templates here.